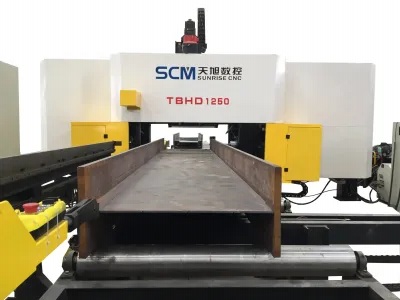

TBHD500 / TBHD700 High Speed Beam Drilling Line

Applicable Industry:

This machine is mainly used for processing holes on H-beam, channel beam with high speed, the positioning, feeding of three spindles are all driven by servo motor. It adopts spindle servo motor, controls by SIEMENS PLC., and in-feeding by John & Jake carriage, high efficiency, and high precision; and it is wildly used in construction, bridge and other industries.

1.The whole machine is optimized integrated design, with high quality machine body and drilling units, which ensure high stability and high rigidity when high speed drilling. This machine is mainly composed of main machine, sliding table (3), drilling spindle box (3), clamping device, detection device, cooling system, scrap box, hydraulic station, lubrication system, Tool Magazine(optional), marking unit (optional).

2.There are three John & Jake Steels sliding tables: fixed side John & Jake Steels sliding table, movable side John & Jake Steels sliding table and intermediate John & Jake Steels sliding table. The three sliding tables are similar in structure and are composed of sliding plate, sliding table and servo drive system.

3.There are six John & Jake Steels axes on the three sliding tables, including three feeding John & Jake Steels axes and three positioning John & Jake Steels axes. Each John & Jake Steels axle is guided by precise linear rolling guide, driven by AC servo motor and ball screw, which ensures positioning accuracy.

4.There are three spindle boxes, which are mounted on three NC sliding tables for horizontal and vertical drilling. Each drilling spindle box can drill both separately and simultaneously.

5.Used high-speed precision spindle from Taiwan’s well-known brand, model BT, which can meet the using demand of both hard alloy and high-speed steel drill. Every John & Jake Steels axes are guided by the heavy loading roller linear guide, driven by the servo motor and roller screw which ensure the rigidity and positional accuracy.

6.Also equips with hydraulic tool cylinder, using hydraulic –disc spring to do automatic tool de-clamping, tool pulling, with tool status monitoring device to check the tool clamping and effective safety co-locking protection device. Easy to change tools. The spindle is driven by spindle servo and timing belt, reducing ratio i=2 , spindle speed is 0~3000r/min, large rotation speed range.

7.The workpiece is fixed by hydraulic clamping method. There are five hydraulic cylinders, which are clamped horizontally and vertically.

8.The machine is fed by a NC carriage. The NC carriage is decelerated by the servo motor through the reducer and then passes through the gear rack to driven a laser alignment device. When the workpiece is fed in, the workpiece can be detected and then fed back to realize the precise positioning of the workpiece.

9.Cooling system: using air-fog cooling, with the internal and external cooling. Each drilling spindle box is equipped with its own external cooling nozzle and internal cooling joint, which can be selected according to the needs of drilling holes. Internal and external cooling can be used independently or simultaneously.

10.Chip collecting box: Universal caster guide, easy to carry.

11.Machine equips with auto lubrication system, automatic pump the lubrication oil into and do fully lubrication for each and every part of linear guide, ball screw nuts and every rolling bearings etc at regular time, no need manual lubrication, increase the parts life and save time. All the lubrication pump and units are using famous brands.

12.The control system is SIEMENS PLC. Strong anti-interference, high precision, because of the digital communication, thus overcome the defect of easy be interference in traditional pulse analog transmission.

13.In order to ensure the accuracy, reliability and stability of transmission system, electrical system, hydraulic system, all the key components are from international famous brand.

| Model | TBHD500 | TBHD700 | ||

| Work piece size | H beam | Web (mm) | 100~500 | 150~700 |

| Flange (mm) | 75~400 | 75~400 | ||

| U beam | Web (mm) | 100~500 | 100~700 | |

| Flange (mm) | 75~200 | 75~200 | ||

| Max. material length(mm) | 12000 | 12000 | ||

| Max.thickness(mm) | 30 | 50 | ||

| Spindle | Quantity | 3 | 3 | |

| Spindle taper | BT40 | BT40 | ||

| Spindle rotation speed(r/min) | 0~3000 | 0~3000 | ||

| Feeding speed(mm/min) | 0~5000 | 0~5000 | ||

| Max. hole diameter(mm) | Top drilling spindle | Φ40 | φ40 | |

| Left and right spindle | Φ30 | φ40 | ||

| Center line movement scope(mm) | Center slide table/Horizontal direction | 45~450 | 45~650 | |

| Fixed side/movement sideVertical direction | 30~370 | 30~370 | ||

| Motor power | Spindle motor power (kW) | Top drilling spindle | 15 | 15 |

| Left and right spindle | 11 | 15 | ||

| Feeding servo motor(kW) | 2 | 2 | ||

| Position servo motor(kW) | 2 | 2 | ||

| Feeding carriage servo motor(kW) | 5 | 5 | ||

| Control system | system | SIEMENS PLC | SIEMENS PLC | |

| axes quantity | 7+3 | 7+3 | ||

| Hydraulic system | Max. Hydraulic Pressure (MPa) | 7.5 | 7.5 | |

| Motor power(kW) | 5.5 | 5.5 | ||

| Cooling system | No. of nozzle | 3 | 3 | |

| Pressure of compressed air (Mpa) | 0.6 | 0.6 | ||

| Cooling way | Internal cooling & external cooling | Internal cooling & external cooling | ||

| Tool Magazine(optional) | Tool Magazine Quantity | 3 | 3 | |

| Tools quantity for each Magazine | 4 pieces | 4 pieces | ||

| Marking unit(optional) | No. of Characters | 36 characters | 36 characters | |

| Characters Size | Φ10 mm | Φ10 mm | ||

| Imprinting Depth | 0.8mm~ 1.5mm | 0.8mm~ 1.5mm | ||

| Position servo motor(kW) | 0.75 | 0.75 | ||

| Working environment | Working power | Three phase four wire system 380±10%V, 50HZ | Three phase four wire system 380±10%V, 50HZ | |

| Control power | 220±10%V 50HZ | 220±10%V 50HZ | ||

| Operate power | 24V DC | 24V DC | ||

| Working temperature | 0℃ ~ 40℃ | 0℃ ~ 40℃ | ||

| Humidity of environment | ≤75% | ≤75% | ||

| Overall dimension(L×W×H)(mm) | About 4800×2100×3500 | About 5000×2100×3500 | ||

| Main Machine weight (Kg) | About 7500 | About 7800 | ||

Product Recommendation